Water and Energy Technologies Laboratory

Our Mission

The Water and Energy Technologies Laboratory (WET Lab), takes steps toward the development of energy efficient technologies with lower carbon footprints to target global fresh water scarcity and global warming.

Our research focuses on the design and development of cutting-edge technologies in the field of water and energy by investigating various phenomena rooting in thermal and fluid transport, power generation systems, solar-thermal energy, water-energy nexus, multi-phase flow, phase-change, interfacial science, surface engineering, and control systems in thermal-fluid applications.

We are developing an operating module of two novel water purification techniques aiming at water desalination and fracking water purification along with the commercialization of thermal fan, a component to improve solar thermal energy efficiency. We work with our industry partners such as UMD, UNR, and MSU in this combined efforts to develop and bring these technologies to every part of the world.

Introduction to WET Lab

Zero Liquid Discharge Water Desalination Process using Humidification-DeHumidification

Fund: $2,000,000

Funding Agency: SETO, DOE

Duration: 3 years

The crisis of freshwater shortage around the world is on the rise. Freshwater is incredibly scarce amounting to only 3% of the water reserves in the world, and most is not exploitable for drinking, irrigation or other industrial applications. Significant efforts are laid upon water desalination to cover the daily rising demand of freshwater. However, water desalination is an energy extensive and economically demanding process.

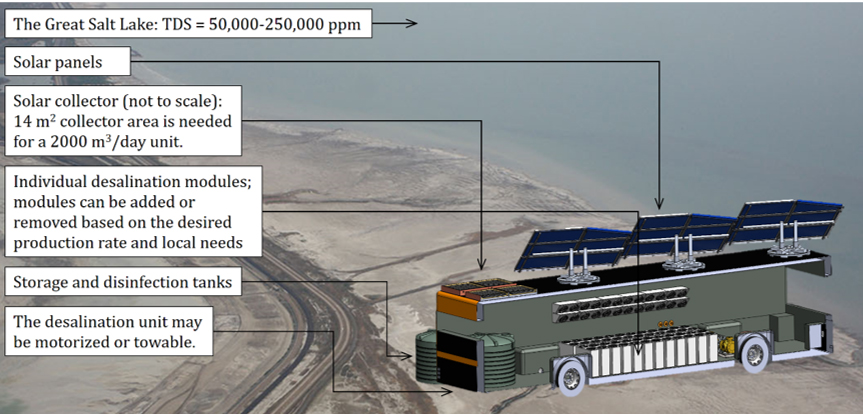

The conventional mechanisms need to be multi-billion dollar projects to meet the plotted thermodynamics and economical efficiencies. This limits their application to specific landscapes and out of reach in rural and secluded areas. In this regard, we present a novel hybrid process to treat highly-saline water with zero liquid discharge. The technology is modular, light-weight, highly portable, scalable, and operates on low grade thermal energy which make it self-contained and capable to access different locations.

The system is designed to treat saline water with over 100,000 ppm total dissolved solids with a minimal specific thermal energy consumption of 54 kWhth/m3 of freshwater. Also, it is designed to provide 2000 m3 of freshwater/day to suffice the need of 6000 Americans at a very competitive cost. At international level, especially in developing countries with abundant sun supply and unreliable electricity like many African nations, it may supply potable water to 70,000 people.

Freshwater Recovery System for Hydraulic Fracturing (FRESH-Frac) using a Thermally-Actuated Nozzle-Demister

FUND: $3,000,000

FUNDING AGENCY: ARPAE, DOE

DURATION: 3 years

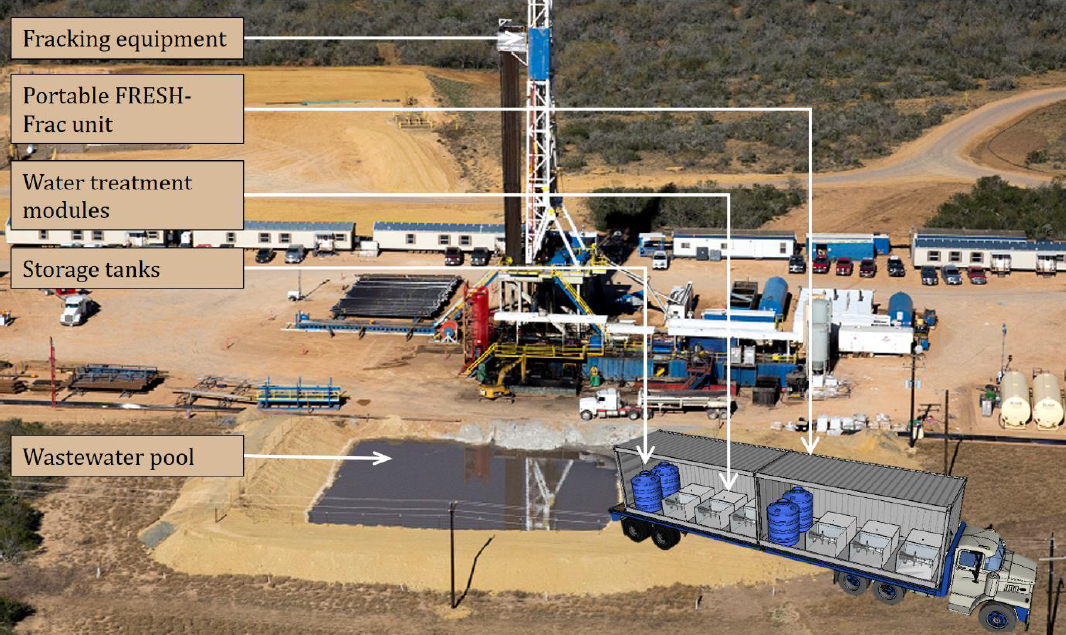

Hydraulic fracturing, or fracking, is the practice of injecting high-pressure water into rock formations to access otherwise inaccessible oil and gas. Fracking a single well requires between one and four million gallons of water. Given the water intensity of fracking, salvaging some of this water for reuse is imperative.

The wastewater that returns to the surface contains significant concentrations of toxic contaminants, which vary based on geology, additives from the fracking process, and time. The majority of wastewater is reinjected into disposal wells, leading to leaks and seepage into freshwater reservoirs. The presence of these contaminants in drinking water causes serious health problems. Treatment of fracking wastewater poses a number of challenges, including the variation in contaminant makeup and portability. It is critical that any wastewater treatment system produces clean water regardless of the influent contaminant makeup, as it is impossible to know the exact contaminants present in any given wastewater.

Fracking wastewater treatment needs to be portable because the wastewater is produced primarily within the well’s first few weeks of operation. In that timeframe building a treatment facility for each well is not economically feasible. Due to the many challenges of treating fracking wastewater almost all of the wastewater is reinjected rather than treated. Traditional wastewater treatment methods are not suited to the variable composition of fracking wastewater. To solve this problem, we use humidification-dehumidification in a thermally-actuated swirling nozzle to extract clean irrigation water from fracking wastewater using low-grade heat. This technology drastically reduces the cost of treating wastewater, making domestic fuel production more competitive and circumventing health concerns associated with fracking wastewater disposal.

Thermal Fan: A Step Toward Energy Sustainability

FUND: $120,000

FUNDING AGENCY: Murdock Foundation + OSU

DURATION: 1 year

Ever growing industrialization and world population has significantly increased the energy demand, and intrigued researchers to look for cheap and clean renewable energy sources. Solar thermal energy and industrial waste heat have been identified as potential candidates. However, significant fraction of these energy sources lies in low-grade heat, which poses serious challenges such as low recovery, and bigger component size. Therefore, a novel concept of thermal fan has been developed, which is capable of producing significantly high mechanical energy while operating at low-grade heat. It demonstrates significantly high heat transfer rates even at lower temperatures via phase-change heat transfer, and thus, improving the recovery rate as well as making it a compact system. This has been identified as the best project of the year at Oregon State University (OSU) for 2020.