OSU-Cascades Makerspace provides design consulting and prototyping services which are open to any company or individual interested. Fee For Service rate is based on material cost and student/staff hours put into design modification and prototype manufacturing. Please contact Dr. Xiang Zhang for more information.

Request for Makerspace Services

Past Projects

Desktop Sculpture

Different desktop sculptures were created by the staff in the Makerspace for the OSU-Cascades administrative awards. The sculptures were designed with CAD software (SolidWorks and Fusion360), prototyped using FDM / MSLA 3D printers and desktop CNC, and then fabricated and post-processed, all in the Makerspace. This project allowed for custom made one-of-a-kind award to be individually produced. Shown here are a few of the final prototypes.

Replacement's Modification & Fabrication

Based on the initial request and in-person discussion with the client, the Makerspace staff modified and fabricated a replacement for an internal component of this handle which had failed. A CAD design was created per measurements of the broken piece, and reinforcement was added to the initial failing area. The Makerspace staff also made the replacement component stronger than the original one by utilizing a 3D print infill pattern to increase the component’s resistance to shear forces.

Grain Hopper

This drone-carried granule dispenser was designed and made by the Makerspace staff in collaboration with a local company in Bend. This project involved a series of prototypes that were all 3D printed and assembled by Makerspace staff. Makerspace staff went through 3 prototypes before arriving at the final version that was delivered. Shown here is the exploded-view drawing of final version we made for this contract. The final assembly was made with repairability and maintenance in mind. With all the parts able to be reprinted by the customer and the electronics being easily accessible. The hopper can hold a selection of different types of granules and the auger at the base of the device slowly pushes the material out.

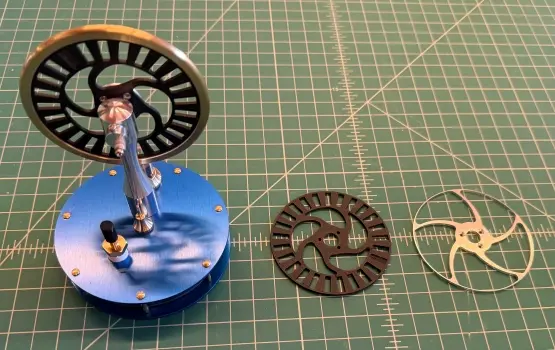

Stirling Engine Assembly & Modification

This small Stirling engine was modified and assembled by the Makerspace staff to assist with analysis of this machine in a classroom setting. Holes were tapped on the aluminum plate to allow for installation and use of a pressure sensor. The custom flywheel was modified and fabricated on a Prusa MK4 3D printer and are designed to help students record the RPMs of the wheel.

Small Electronics Component

This set of small electronics components was designed by a local branch of a national engineering company. The design was reviewed and modified based on the recommendations provided by Makerspace employee considering its application and the selected fabrication approach. The prototype was 3D printed using a Formlabs Form 3L SLA printer. It was made using an engineering grade, high temperature resistant resin, as was necessary for this component’s application.

Pressure Regulated Seed Distributor

This pressure regulated seed distributor was designed and fabricated by the Makerspace staff in collaboration with a local company in Bend, OR. This project involved 3D printed and laser-cut parts assembled by Makerspace staff. Shown here is the final product. The seed distributor is intended to be used with a vacuum whose input is regulated by the input/output adjusters located on the sides of the lower box. The top has a matrix of 0.51 mm holes made to attract one seed apiece. Once flipped over, it is placed atop a seedling tray where the seeds drop directly into their respective planter holes once vacuum is off.

Laser Engraved & 3D Printed Puzzle Box

Based on the Fee for Service request through email and discussion with the client over the phone, the Makerspace staff assisted the client in fabricating a custom-designed puzzle box using laser engraver and 3D printers available in the space. Advices regarding how to operate the laser engraver and how to set up the 3D print were provided during the process, and the client successfully fabricated the puzzle box within a few hours to meet the project deadline.